This is the third instalment in a 4-part series. If you haven’t read the previous post, you can find that here.

Picture this; you’ve just completed your 11th scan for the day and your last patient was an absolute nightmare. Your shoulders are stiff, your wrist is sore & you want nothing more than to finish your day and go home. Despite this, you know how important it is to take care of your equipment, so you begrudgingly begin the process of pre-cleaning and disinfecting your transducer. After washing with a mild soap to remove gel and debris, you towel dry with a lint-free cloth and wipe the probe down with isopropyl. Once again, you towel dry and then hang it up – a process you’ve come to know like the back of your hand after performing it hundreds of times on different non-critical probes. But you’ve likely just made a critical error.

Did you know that using alcohol on your probes can cause more harm than good?

The most important part of any cleaning procedure is to always follow the manufacturer’s guidelines. These guides are put in place to prevent unnecessary damage, and to prolong the lifespan of your transducer. Most ultrasound probe manufacturers warn against the use of alcohol-based disinfectants, but why? Because of the chemical composition of your probe, repeated or long-term exposure to alcohol can cause chemical reactions with the plastics, and silicones. This can lead to denaturing of your probe’s lens, cracking of the strain relief, and discolouration of the casing.

So, will it affect your imaging?

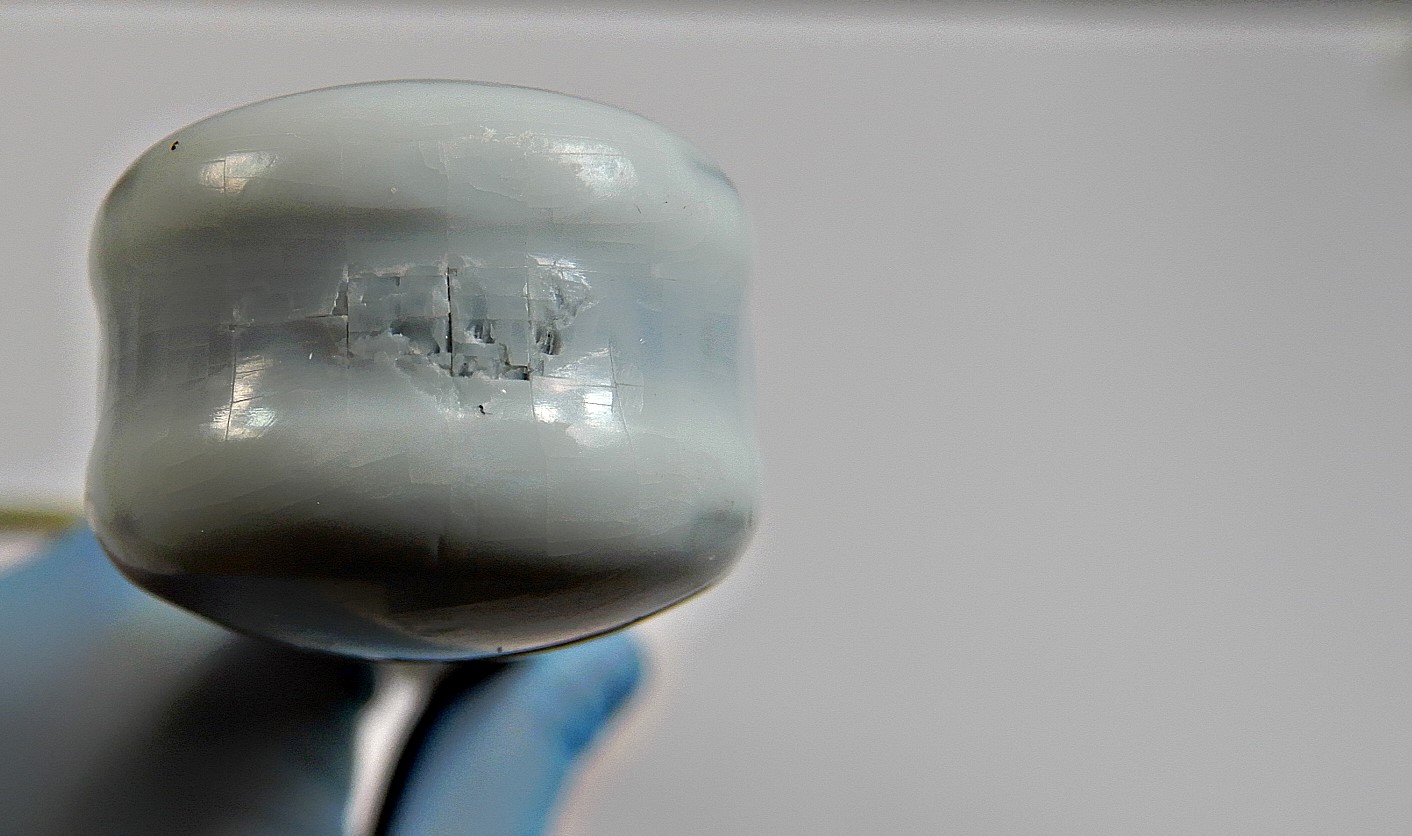

Repeatedly using chemicals or solutions that are not approved in your manufacturer’s guidelines, can have severe effects on your probe’s lifespan and imaging capabilities. For example, if the protective coating on your lens dries out, it can crack or flake, exposing the delicate acoustic array to damage such as delamination, fluid ingress, impact related faults such as image drop out, or dead elements. This also becomes a risk to yourself and your patients through the possibility of bacterial cross-contamination. Transducer’s are designed with optimised cleaning in mind, so when the smooth silicone starts to flake, crevices form, harbouring nasty bacteria which can be transferred from patient to patient, or to contact surfaces. It is important to note that while the lens provides a protective barrier for the delicate acoustic array, it also acts as an electrical insulator to protect you and your patient. When this protective barrier is compromised, using the transducer becomes an electrocution risk.

Below is an example of a dry flaking lens affected by alcohol.

But what if you only use alcohol to clean the casing, strain relief and cable?

While lens damage is the largest risk associated with repeated exposure to alcohol, it can also have an effect on other parts of your probe.

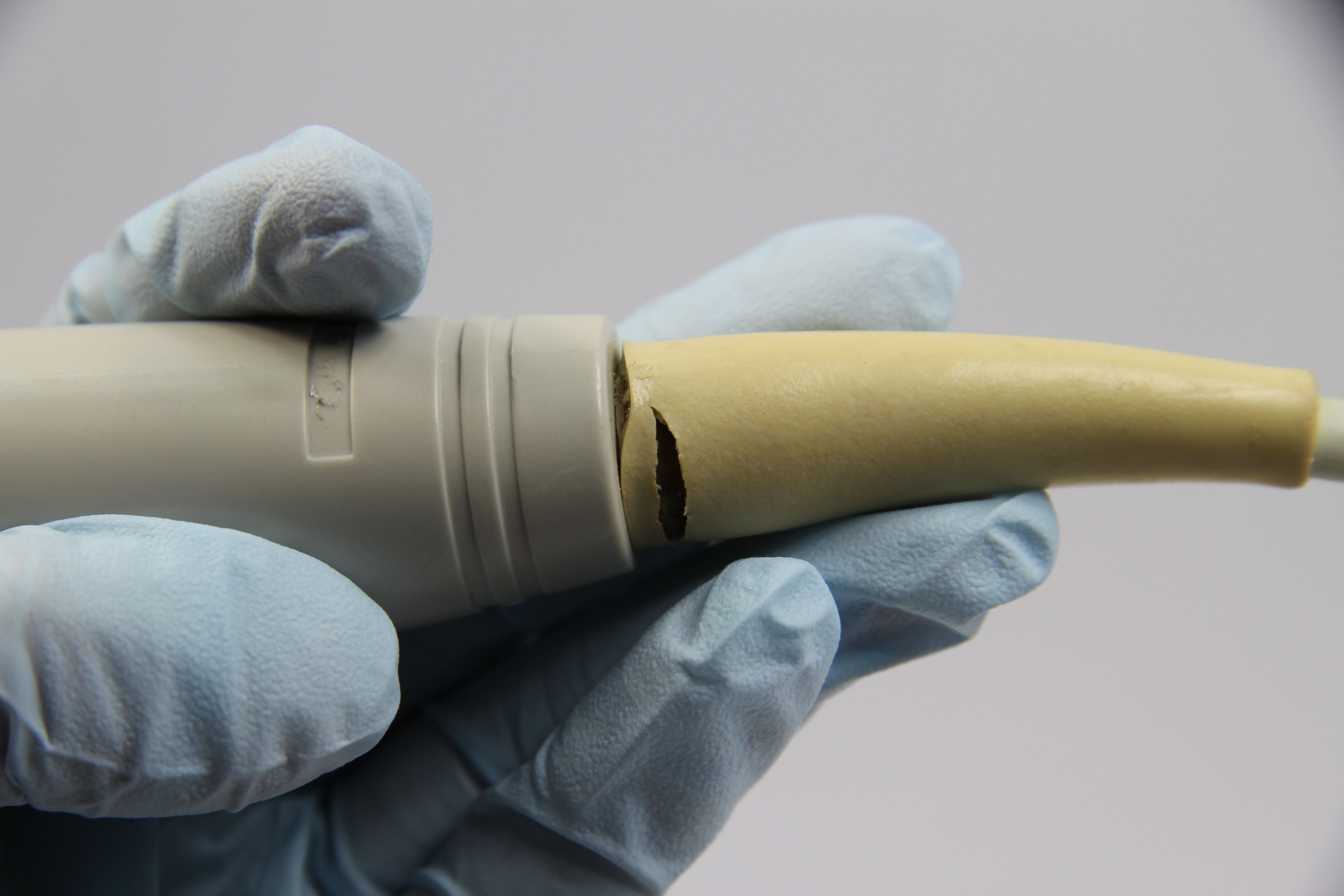

For example, long-term usage can result in the alcohol leeching the plasticisers from the strain relief, which in turn makes it brittle & crack under pressure. The strain relief is important because it reduces the amount of tension and stress that the wires in the cable are exposed to. Of the hundreds of elements in your probe, each is attached to a wire which carries the signal back to your machine. Without a functioning strain relief, these wires can bend or break, leading to artefacts within the image that obscure important details. Below is an example of a strain relief which after repeated exposure to alcohol, has lost it’s elasticity and become dry & brittle.

Come back next week as we debate the importance of manufacturer’s guidelines in regards to cleaning and maintaining your probes.

Coming up next:

Week 4: Do the manufacturer’s guideline’s really matter?