Routine probe testing can reveal probe degradation that is not immediately apparent to the Sonographer or Service Engineer. Our experience has shown that approximately 25% of all probes on ultrasound systems aged 2 years or over, have some form of internal structural defect.

We service all of Australia and New Zealand. If you have any issues with your ultrasound imaging equipment please contact us and we can help you.

Probe testing and analysis is a four step process that will uncover any degradation that has occurred within the entire structure of the transducer.

The transducer undergoes comprehensive testing, including the following:

Visual Inspection

All transducers undergo a thorough visual inspection to identify surface imperfections such as physical damage to the probe case, cable, lens or connector.

Digital Analysis

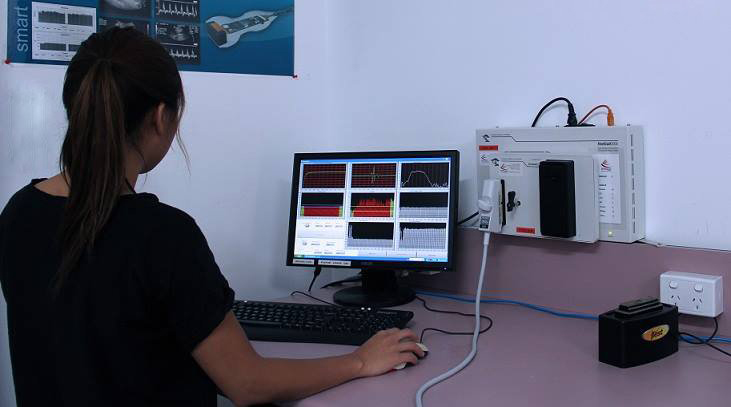

We undertake a quantitative interrogation of the transducer’s electrical and acoustic properties utilising ProbeLogic’s Digital Analyser.

Electrical Safety Testing

All transducers are electrically safety tested to ensure safe operation. This is paramount for all intracavitary probes.

Probe-Specific Testing

Not all probes are alike. Transducers may undergo additional testing procedures as relevant to their make/model or specified fault, including, but not limited to:

- 3D probe functionality testing

- TOE/TEE probe functionality testing

- Pneumatic leakage testing

- Machine fault testing

- Microscopy