So, you’ve been told that your strain relief requires work. But is it really important?

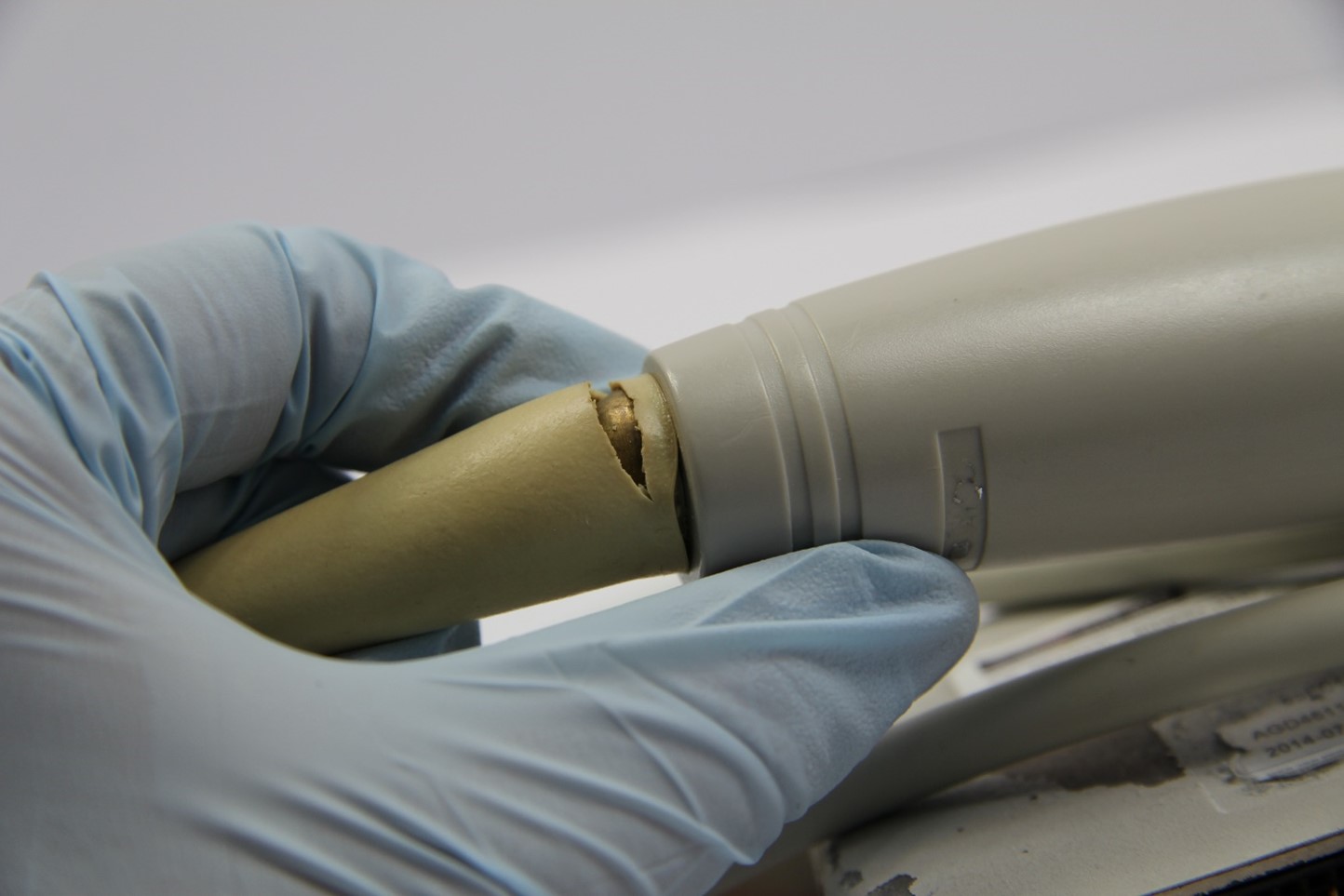

If you have been recommended to repair the strain relief on your probe, it is because we have noticed that it has started to degrade. This usually involves the strain relief starting to separate from the connector or probe head, crack or become stiff.

The strain relief is important because it ensures the cable bends across a large radius instead of just at one single point. This reduces the amount of tension and stress that the wires in the cable are exposed to. Without a functioning strain relief, the wires can develop breaks, leading to dead elements, or artifacts within the image that obscure important details.

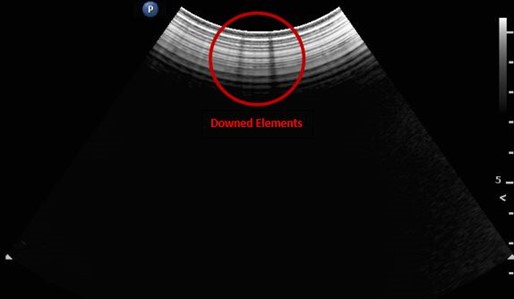

Of the hundreds of elements in your probe, each is attached to a wire which carries the signal back to your machine. If one or more of those wires become damaged, black lines can appear. These are dead elements; below is an example.

Downed elements can prevent you making an accurate diagnosis because they obscure fine details. Mitigate against this risk by having your strain relief repaired as soon as you notice any damage.

————————————————————————————————————————–

So what should you be looking for and checking regularly on your ultrasound probes? Here is a guide

How should you be cleaning your general ultrasound probes? Here is a guide

Sometimes it isn’t always as simple as looking for dropout. In this case you can see that phased array probes don’t show dropout clearly.

It really does make sense to repair your probes instead of taking large service contracts with the OEMs. Especially if you have a fleet of machines so that you can spread your risk. Become your own insurance company with very little risk! Here is some information on this approach

If you require any assistance for anything ultrasound related. Don’t hesitate to contact us.