So, you’ve been told that your need to repair the pins on your connector. But what does this mean? And does it really matter?

The pins on your connector enable your transducer to communicate with the machine it is connected to by transmitting signals.

If your evaluation report has come back indicating pin damage, it usually means that we have detected some form of corrosion, or breakdown of the pin surface. While this may not be cause for concern cosmetically, it has the potential to seriously impair the function of your probe.

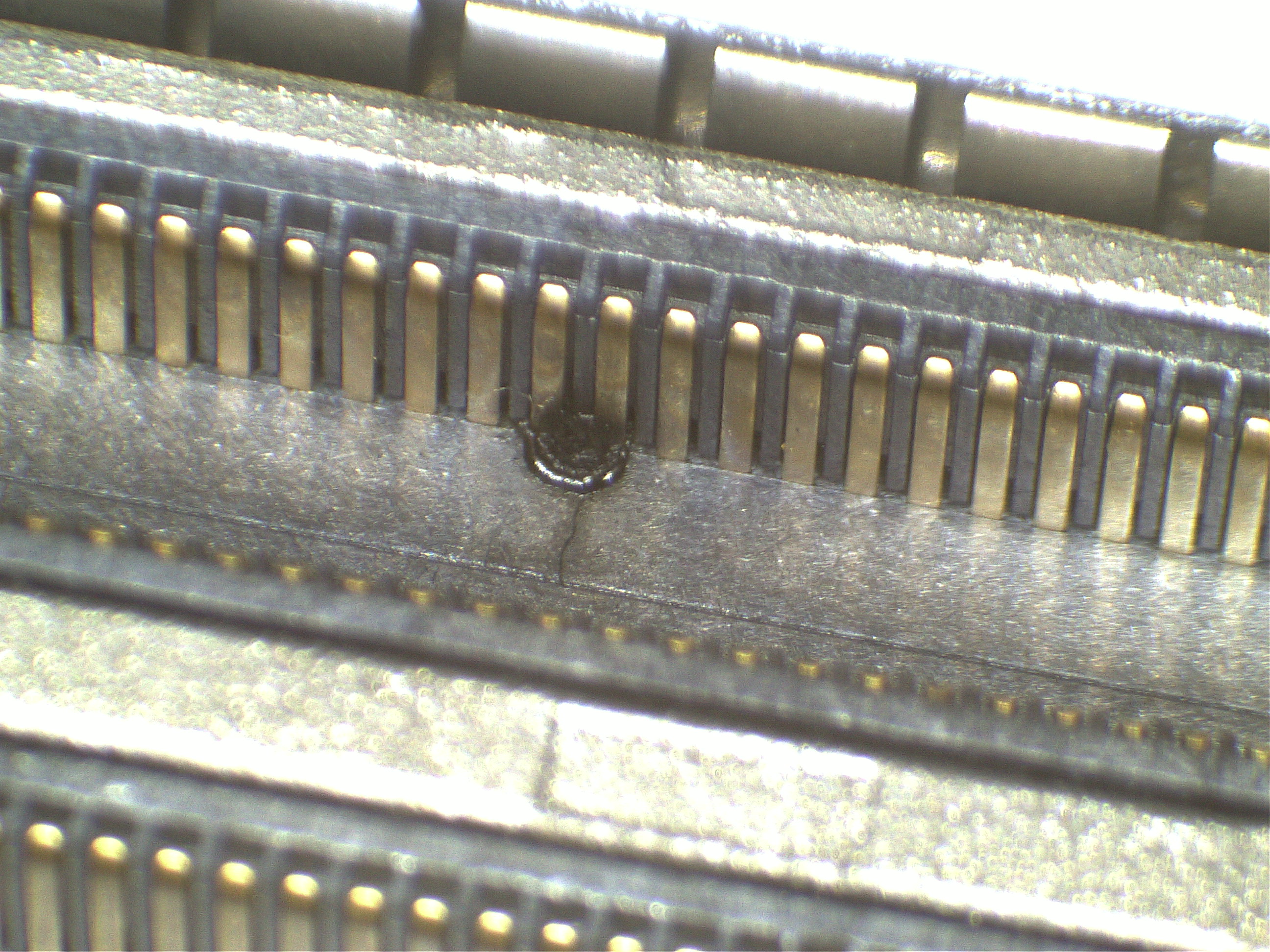

Corrosion on the pins of your connector can deteriorate the signal integrity and prevent a compatible machine from accurately communicating with your probe. In some cases, this means an inability of a machine to recognize that anything has been plugged into it. Corrosion can also cause the connector pins to generate excessive heat, which can actually melt the pins in the connector or the machine.

Below you can see dark spots. This is a visible sign of heating due to electrical faults within the pins.

Corrosion occurs when the metal is exposed to fluid, and corrosion on the pins generally indicates a much larger problem of fluid ingress inside your connector.

You can read about this here.

Other damage to pins may include breaks, bends or displacement which also deteriorate signal integrity and can affect your transducer’s ability to produce images.

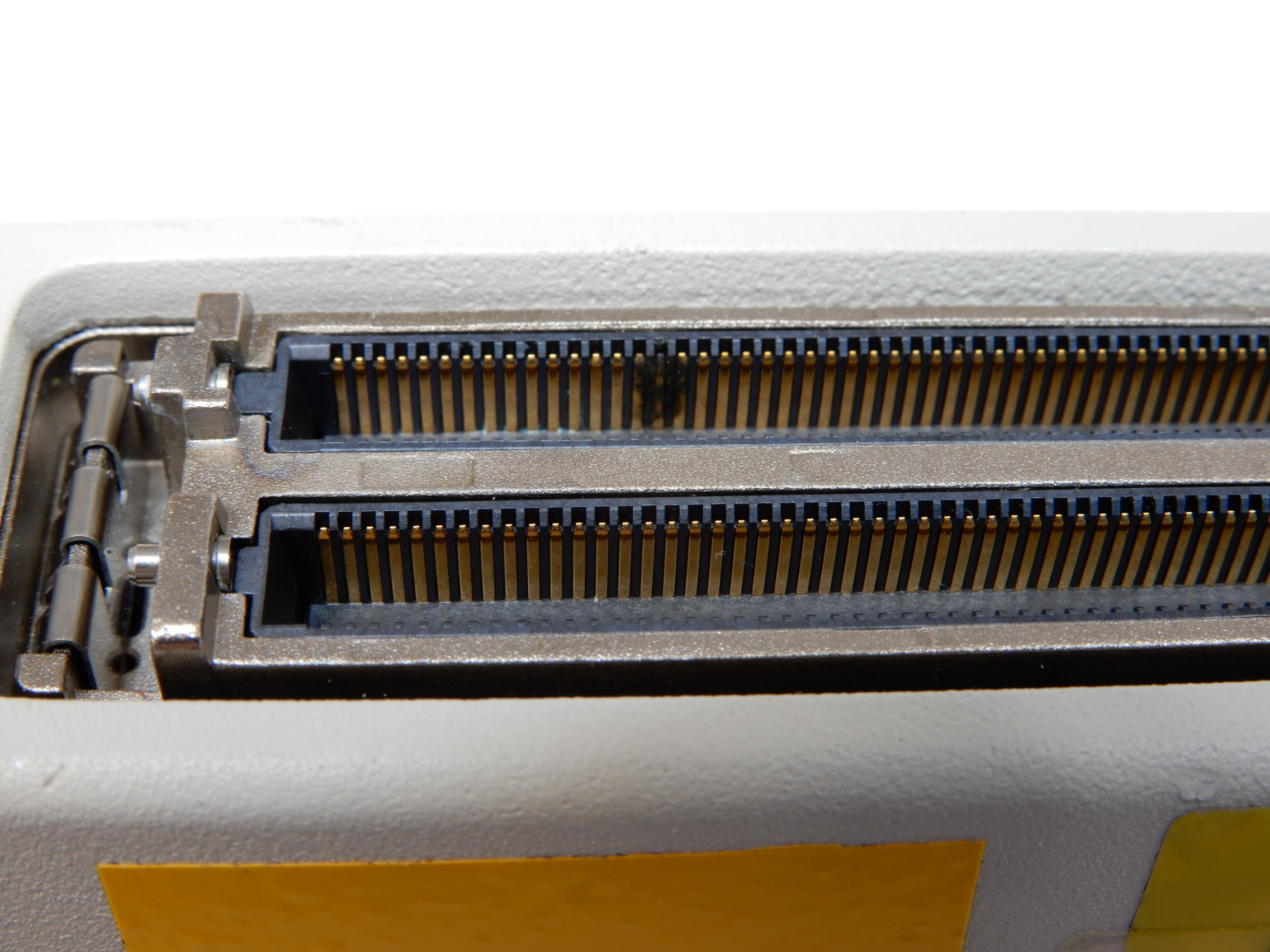

In the images below you can see several pins have visibly bent out of place – likely the result of the connector being dropped or knocked.

So what should you be looking for and checking regularly on your ultrasound probes? Here is a guide

How should you be cleaning your general ultrasound probes? Here is a guide

Sometimes it isn’t always as simple as looking for dropout. In this case you can see that phased array probes don’t show dropout clearly.

It really does make sense to repair your probes instead of taking large service contracts with the OEMs. Especially if you have a fleet of machines so that you can spread your risk. Become your own insurance company with very little risk! Here is some information on this approach

If you require any assistance for anything ultrasound related. Don’t hesitate to contact us.